The stone back bolt is designed to control the installation depth through the screw limit design, which effectively prevents the anchor bolt from passing through the plate and reduces the damage of the plate. Stone back bolts can be roughly divided into these three types. The following editor of FABULOUS Group mainly explains the materials and installation of these three types. Let's understand.

1. Percussion type stone back bolt

1. Material: A2 (304) stainless steel, A4 (316L) stainless steel;

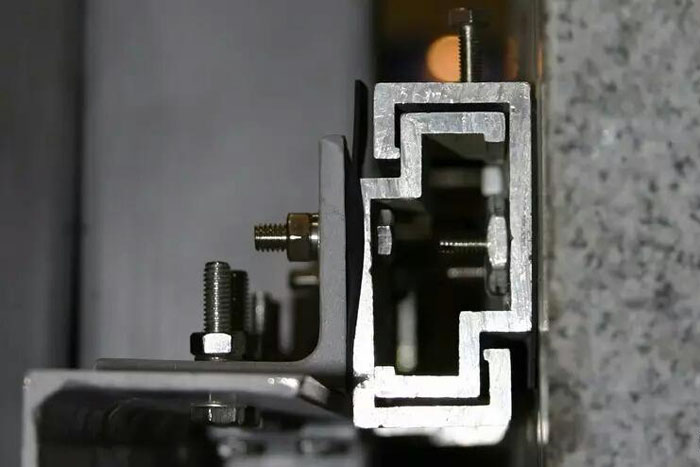

2. Product description: The percussion stone back bolt is composed of a conical screw, a plum blossom diffuser ring, a casing, a flat washer, a spring washer and a hexagonal nut. The bottom of the hole to the inner surface of the stone is a fixed value. The product itself cannot eliminate the error of stone processing, and can only be adjusted in the horizontal direction through the keel system at the rear of the material;

4. Installation: Drilling is completed by the back bolt punching machine and the back bolt punching bit. The stone back bolt is installed by a special installation tool for the back bolt.

Two, double-cut stone back bolt

1. Material: A2 (304) stainless steel, A4 (316L) stainless steel;

2. Product description: The double-cut stone back bolt is composed of a conical screw, a plum blossom diffuser ring, a casing, a flat washer, a spring washer and a hexagonal nut. The bottom of the hole to the inner surface of the stone is a fixed value. The product itself cannot eliminate the stone processing error, and can only be adjusted in the horizontal direction through the keel system at the rear of the stone;

3. Installation: Drilling is completed by the back bolt punching machine and the back bolt drill bit. Install the double-cut stone back bolt by a special installation tool for the back bolt.

Three, screw-in stone back bolt

Material: A2 (304) stainless steel, A4 (316L) stainless steel

Product description: The screw-in stone back bolt is composed of a conical expansion sleeve, an inner hexagonal screw and a flange surface locking non-slip nut. The bottom of the hole to the inner surface of the stone is a fixed value. The product itself cannot eliminate the stone processing error, and can only be adjusted in the horizontal direction through the keel system at the rear of the stone.

Installation: Drilling is completed by the back bolt punching machine and the back bolt punching bit. The screw-in stone back bolt is installed by a special installation tool for the back bolt.

The expansion size of the sleeve is limited by the screw, and there is no extrusion stress on the plate, which is especially suitable for the anchoring of thin plates and brittle plates. For screw-in stone back bolts, the selected nut is a flange-type anti-skid lock nut. After this nut is tightened, it can prevent long-term minor vibrations, which may cause the nut to loosen or fall off. Better guarantee the safety of the back bolt system. The products are widely used in rail transit porcelain panel curtain walls. The expansion size of the sleeve is limited by the screw, the stress is small, and it has good seismic performance and dynamic load bearing performance.

stone back bolt has good corrosion resistance, especially suitable for atmospheric environment containing chloride and sulfur dioxide, the operation is also very convenient, and it is widely used.